Common Production Processes for Capacitor Pictures

I. Introduction

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and power flow. They play a critical role in various applications, from consumer electronics to industrial machinery. As the demand for high-quality capacitors continues to grow, so does the need for effective documentation and marketing strategies. One of the key aspects of this is the use of capacitor pictures, which serve not only as a visual representation of the product but also as a tool for quality control and marketing. In this blog post, we will explore the common production processes for capacitor pictures, delving into the types of capacitors, manufacturing techniques, and the role of imaging in the industry.

II. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications. Understanding these types is crucial for appreciating the production processes involved.

A. Electrolytic Capacitors

Electrolytic capacitors are polarized components that offer high capacitance values in a compact size. They are commonly used in power supply circuits and audio applications.

B. Ceramic Capacitors

Ceramic capacitors are non-polarized and known for their stability and reliability. They are widely used in high-frequency applications and are often found in RF circuits.

C. Film Capacitors

Film capacitors utilize a thin plastic film as the dielectric material. They are known for their low loss and high insulation resistance, making them suitable for audio and power applications.

D. Tantalum Capacitors

Tantalum capacitors are known for their high capacitance-to-volume ratio and stability. They are often used in applications where space is limited, such as in mobile devices.

E. Supercapacitors

Supercapacitors, or ultracapacitors, offer high energy density and rapid charge/discharge capabilities. They are increasingly used in energy storage systems and hybrid vehicles.

F. Comparison of Different Types and Their Applications

Each type of capacitor has its advantages and disadvantages, making them suitable for specific applications. Understanding these differences is essential for manufacturers and consumers alike.

III. Overview of Capacitor Production Processes

The production of capacitors involves several intricate processes, each contributing to the final product's quality and performance.

A. Raw Material Selection

The first step in capacitor production is the selection of raw materials. This includes choosing appropriate dielectric materials and electrodes.

1. **Types of Materials Used**: Common dielectric materials include ceramic, plastic film, and electrolytic solutions. The choice of electrode material, such as aluminum or tantalum, also plays a significant role in the capacitor's performance.

2. **Quality Control Measures for Raw Materials**: Ensuring the quality of raw materials is critical. Manufacturers often implement stringent quality control measures, including testing for purity and consistency.

B. Manufacturing Techniques

The manufacturing process involves several key techniques that contribute to the capacitor's functionality.

1. **Dielectric Layer Formation**: The dielectric layer is crucial for a capacitor's performance. Methods such as chemical vapor deposition (CVD) and physical vapor deposition (PVD) are commonly used to create this layer. The thickness and uniformity of the dielectric are vital for ensuring optimal capacitance.

2. **Electrode Preparation**: The preparation of electrodes involves various techniques, including etching and coating. The choice of electrode material affects the capacitor's voltage rating and overall performance.

3. **Assembly Process**: The assembly process includes stacking and winding the layers of dielectric and electrodes. This is followed by encapsulation and sealing to protect the capacitor from environmental factors.

C. Testing and Quality Assurance

Once the capacitors are manufactured, they undergo rigorous testing to ensure they meet industry standards.

1. **Electrical Testing**: This includes measuring capacitance, equivalent series resistance (ESR), and leakage current to ensure the capacitor functions as intended.

2. **Environmental Testing**: Capacitors are subjected to various environmental tests, including temperature and humidity tests, to assess their reliability under different conditions.

3. **Visual Inspection and Imaging Techniques**: Visual inspection is essential for identifying defects. Imaging techniques, such as high-resolution photography, are used to document the appearance of capacitors for quality control.

IV. The Role of Imaging in Capacitor Production

Imaging plays a crucial role in the production and marketing of capacitors. High-quality images are essential for documentation and presentation.

A. Importance of High-Quality Images

1. **Documentation for Quality Control**: High-resolution images help manufacturers document the appearance of capacitors, making it easier to identify defects and ensure quality.

2. **Marketing and Product Presentation**: In a competitive market, high-quality images are vital for attracting customers. They provide a visual representation of the product, helping potential buyers understand its features and benefits.

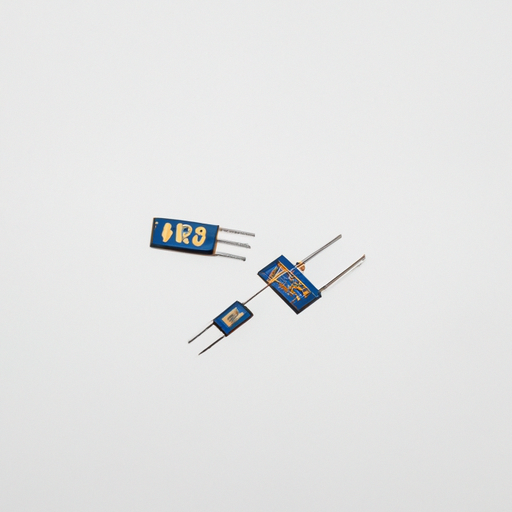

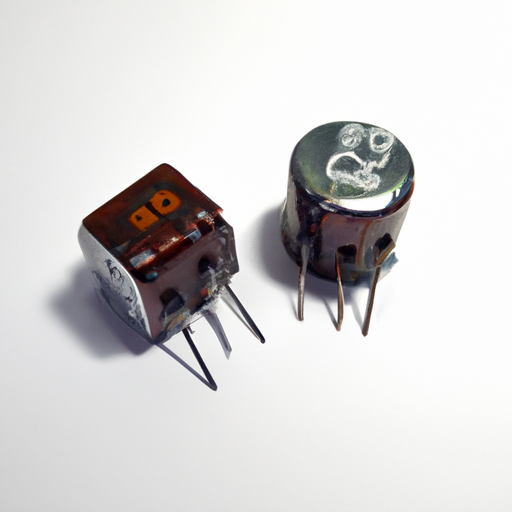

B. Techniques for Capturing Capacitor Images

1. **Photography Basics**: Effective capacitor photography requires attention to lighting, angles, and backgrounds. Proper lighting enhances the details of the capacitor, while the right angle can showcase its features.

2. **Use of Macro Photography for Detailed Images**: Macro photography allows for close-up shots that capture intricate details, such as markings and textures, which are essential for documentation and marketing.

3. **Digital Imaging Software for Enhancement and Editing**: Post-processing software can enhance images, correcting colors and improving clarity. This is particularly useful for creating professional-looking product images.

V. Challenges in Capacitor Production and Imaging

Despite advancements in technology, several challenges persist in capacitor production and imaging.

A. Variability in Raw Materials

Variability in the quality of raw materials can lead to inconsistencies in capacitor performance. Manufacturers must implement strict quality control measures to mitigate this issue.

B. Precision in Manufacturing Processes

The precision required in manufacturing processes is critical. Even minor deviations can affect the capacitor's performance, making it essential for manufacturers to maintain high standards.

C. Maintaining Consistency in Imaging

Achieving consistent imaging quality can be challenging, especially when dealing with different lighting conditions and backgrounds. Standardizing imaging processes can help address this issue.

D. Addressing Environmental Factors in Production

Environmental factors, such as temperature and humidity, can impact the manufacturing process. Manufacturers must create controlled environments to ensure consistent production quality.

VI. Future Trends in Capacitor Production and Imaging

The capacitor industry is evolving, with several trends shaping its future.

A. Advances in Materials Science

Research into new materials is leading to the development of capacitors with improved performance characteristics, such as higher capacitance and lower leakage.

B. Automation and Smart Manufacturing

Automation is streamlining the manufacturing process, increasing efficiency and reducing the likelihood of human error. Smart manufacturing technologies are also enabling real-time monitoring and quality control.

C. Innovations in Imaging Technology

Advancements in imaging technology, such as 3D imaging and augmented reality, are enhancing the way capacitors are documented and marketed.

D. Sustainability in Capacitor Production

As environmental concerns grow, manufacturers are increasingly focusing on sustainable practices, including the use of eco-friendly materials and processes.

VII. Conclusion

In conclusion, the production processes for capacitor pictures are multifaceted, involving various types of capacitors, intricate manufacturing techniques, and the critical role of imaging. High-quality images are essential for documentation and marketing, helping manufacturers present their products effectively. As the industry continues to evolve, advancements in materials science, automation, and imaging technology will shape the future of capacitor production and imaging practices. By understanding these processes, manufacturers can enhance their product offerings and meet the growing demands of the electronic device market.

VIII. References

1. Academic journals and articles on capacitor technology and manufacturing processes.

2. Industry reports and white papers detailing advancements in capacitor production.

3. Books on capacitor technology, including their applications and future trends.