Understanding Capacitor Film: A Comprehensive Guide

I. Introduction

Capacitors are essential components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. Among the various types of capacitors, film capacitors stand out due to their unique properties and applications. This article aims to provide a comprehensive understanding of capacitor film, exploring its definition, construction, applications, and performance characteristics, while also comparing it to other capacitor types.

II. What is a Capacitor?

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store energy.

A. Basic Definition and Function

The primary function of a capacitor is to store and release electrical energy. This ability makes capacitors vital in various applications, including power supply smoothing, signal coupling, and timing circuits.

B. Types of Capacitors

Capacitors come in several types, each with distinct characteristics and applications:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and typically used in power supply applications.

2. **Ceramic Capacitors**: These capacitors are non-polarized and offer stability and reliability, making them suitable for high-frequency applications.

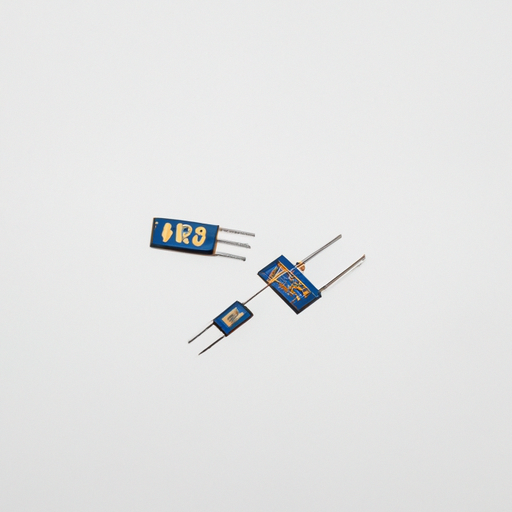

3. **Film Capacitors**: These capacitors use a thin plastic film as the dielectric and are known for their excellent performance in various applications.

C. Overview of Capacitor Construction

Capacitors are constructed from two conductive plates and a dielectric material. The choice of dielectric material significantly influences the capacitor's performance characteristics, such as capacitance, voltage rating, and temperature stability.

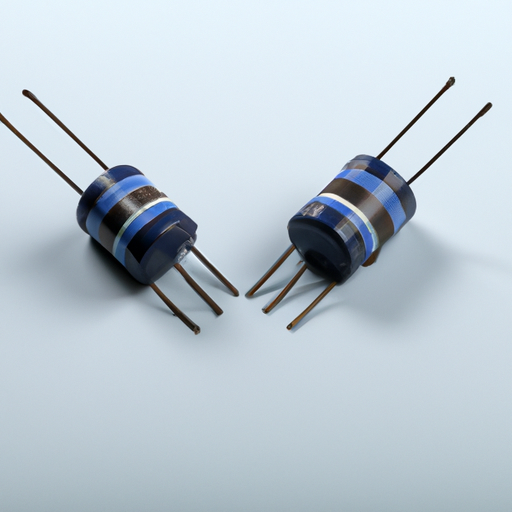

III. Understanding Film Capacitors

A. Definition and Characteristics

Film capacitors are a type of capacitor that uses a thin plastic film as the dielectric material. They are known for their stability, low self-inductance, and high insulation resistance, making them suitable for a wide range of applications.

B. Types of Film Capacitors

Film capacitors can be categorized based on the type of dielectric material used:

1. **Polyester Film Capacitors**: These are widely used due to their cost-effectiveness and decent performance characteristics.

2. **Polypropylene Film Capacitors**: Known for their excellent electrical properties, these capacitors are often used in high-frequency applications.

3. **Polycarbonate Film Capacitors**: These capacitors offer good temperature stability and are suitable for applications requiring high reliability.

4. **Other Types**: Other film capacitors include those made from materials like PTFE (Teflon) and PVC, each offering unique benefits.

C. Advantages of Film Capacitors Over Other Types

Film capacitors have several advantages over other capacitor types, including:

Stability and Reliability: Film capacitors exhibit minimal changes in capacitance over time and under varying environmental conditions.

Low Self-Inductance: This characteristic allows film capacitors to perform well in high-frequency applications.

High Insulation Resistance: Film capacitors provide excellent insulation, reducing the risk of leakage currents.

IV. Construction of Film Capacitors

A. Materials Used in Film Capacitors

The construction of film capacitors involves specific materials that contribute to their performance:

1. **Dielectric Materials**: The dielectric is typically made from plastic films such as polyester, polypropylene, or polycarbonate.

2. **Metal Foils**: The conductive plates are usually made from aluminum or other conductive metals.

B. Manufacturing Process

The manufacturing process of film capacitors involves several steps:

1. **Film Production**: The dielectric film is produced through extrusion or casting processes.

2. **Layering and Winding**: The metal foils are layered with the dielectric film and wound into a cylindrical shape.

3. **Encapsulation and Finishing**: The wound capacitor is encapsulated in a protective material to ensure durability and reliability.

V. Applications of Film Capacitors

Film capacitors are used in a wide range of applications, including:

A. Consumer Electronics

In consumer electronics, film capacitors are commonly found in audio equipment, televisions, and computers, where they help filter signals and stabilize power supplies.

B. Industrial Applications

Film capacitors are used in industrial machinery for power factor correction, motor starting, and energy storage applications.

C. Automotive Electronics

In the automotive industry, film capacitors are utilized in various electronic control units, sensors, and power management systems.

D. Renewable Energy Systems

Film capacitors play a crucial role in renewable energy systems, such as solar inverters and wind turbine controllers, where they help manage energy flow and improve efficiency.

E. Audio and Video Equipment

High-fidelity audio and video equipment often employs film capacitors for their superior performance in signal processing and filtering.

VI. Performance Characteristics

A. Capacitance Range

Film capacitors are available in a wide range of capacitance values, typically from a few picofarads to several microfarads, making them suitable for various applications.

B. Voltage Ratings

Film capacitors come with different voltage ratings, allowing them to be used in low-voltage and high-voltage applications.

C. Temperature Stability

Film capacitors exhibit excellent temperature stability, maintaining their performance across a wide temperature range.

D. Frequency Response

Film capacitors have a high-frequency response, making them ideal for applications that require fast signal processing.

E. Lifespan and Reliability

With a long lifespan and high reliability, film capacitors are often preferred in applications where durability is essential.

VII. Advantages and Disadvantages of Film Capacitors

A. Advantages

1. **Stability and Reliability**: Film capacitors maintain their performance over time, making them a reliable choice for critical applications.

2. **Low Self-Inductance**: This characteristic allows for better performance in high-frequency circuits.

3. **High Insulation Resistance**: Film capacitors minimize leakage currents, enhancing overall circuit efficiency.

B. Disadvantages

1. **Size and Weight Considerations**: Film capacitors can be larger and heavier than other types, which may be a drawback in compact designs.

2. **Cost Factors**: While film capacitors offer excellent performance, they can be more expensive than other capacitor types, such as electrolytic capacitors.

VIII. Comparison with Other Capacitor Types

A. Film Capacitors vs. Electrolytic Capacitors

Film capacitors are generally more stable and reliable than electrolytic capacitors, which can suffer from degradation over time. However, electrolytic capacitors offer higher capacitance values in a smaller size.

B. Film Capacitors vs. Ceramic Capacitors

While ceramic capacitors are smaller and often less expensive, film capacitors provide better stability and performance in high-frequency applications.

C. When to Choose Film Capacitors Over Other Types

Film capacitors are ideal for applications requiring high reliability, stability, and low self-inductance, such as audio equipment, industrial machinery, and renewable energy systems.

IX. Future Trends in Film Capacitor Technology

A. Innovations in Materials and Design

Advancements in materials science are leading to the development of new dielectric materials that enhance the performance of film capacitors, allowing for smaller sizes and higher capacitance values.

B. Impact of Technology on Performance and Applications

As technology continues to evolve, film capacitors are expected to find new applications in emerging fields such as electric vehicles, smart grids, and advanced telecommunications.

C. Sustainability and Environmental Considerations

With growing concerns about environmental impact, manufacturers are exploring sustainable materials and production processes for film capacitors, aiming to reduce their carbon footprint.

X. Conclusion

In summary, understanding capacitor film is essential for anyone involved in electronics, from hobbyists to professionals. Film capacitors offer unique advantages, including stability, reliability, and excellent performance in various applications. As technology advances, the role of film capacitors in modern electronics will continue to grow, making it worthwhile to explore and learn more about this vital component.

XI. References

For further reading and resources on film capacitors, consider exploring industry standards, technical papers, and manufacturer guidelines. Understanding the specifications and applications of film capacitors can enhance your knowledge and expertise in electronics.