Market Policies for Air Conditioning Capacitors

I. Introduction

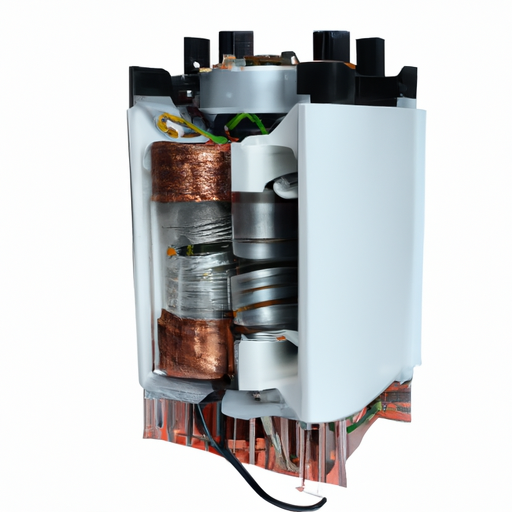

Air conditioning capacitors are essential components in HVAC (heating, ventilation, and air conditioning) systems, playing a critical role in the efficient operation of air conditioning units. These electrical devices store and release energy, helping to stabilize voltage and improve the performance of motors and compressors. As the demand for air conditioning systems continues to rise, particularly in the face of climate change and increasing global temperatures, understanding the market policies that govern air conditioning capacitors becomes increasingly important. This blog post will explore the regulatory frameworks, market dynamics, pricing strategies, technological innovations, environmental considerations, and the challenges and opportunities that shape the air conditioning capacitor market.

II. Regulatory Framework

A. Government Regulations

Government regulations play a pivotal role in shaping the air conditioning capacitor market. These regulations often focus on two primary areas: environmental impact and energy efficiency.

1. **Environmental Regulations**: Many countries have implemented stringent environmental regulations aimed at reducing the carbon footprint of HVAC systems. These regulations often dictate the types of materials that can be used in capacitor manufacturing, promoting the use of eco-friendly alternatives.

2. **Energy Efficiency Standards**: Energy efficiency standards are designed to ensure that air conditioning systems, including their capacitors, operate at optimal efficiency. In the United States, for example, the Department of Energy (DOE) sets energy efficiency standards that manufacturers must meet, which can influence the design and production of capacitors.

B. Industry Standards

In addition to government regulations, industry standards established by organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) provide guidelines for the safety and performance of air conditioning capacitors. Compliance with these standards is crucial for manufacturers, as it ensures product reliability and safety, thereby fostering consumer trust.

C. Compliance Requirements for Manufacturers

Manufacturers of air conditioning capacitors must navigate a complex landscape of compliance requirements. This includes obtaining certifications for their products, adhering to safety standards, and ensuring that their manufacturing processes meet environmental regulations. Non-compliance can result in significant penalties, product recalls, and damage to a company's reputation.

III. Market Dynamics

A. Supply and Demand Factors

The air conditioning capacitor market is influenced by various supply and demand factors.

1. **Seasonal Demand Fluctuations**: Demand for air conditioning systems—and consequently, capacitors—tends to peak during the summer months when temperatures rise. Manufacturers must be prepared to scale production to meet this seasonal demand.

2. **Impact of Climate Change on Demand**: As global temperatures continue to rise due to climate change, the demand for air conditioning systems is expected to increase. This trend will likely drive up the demand for capacitors, prompting manufacturers to innovate and improve their products.

B. Key Players in the Market

The air conditioning capacitor market is characterized by a mix of major manufacturers, distributors, and retailers. Key players include companies that specialize in HVAC components, as well as larger corporations that produce a wide range of electrical components. Understanding the competitive landscape is essential for stakeholders looking to enter or expand within this market.

C. Market Segmentation

The market for air conditioning capacitors can be segmented into residential and commercial applications. Residential applications typically involve smaller capacitors for home air conditioning units, while commercial applications may require larger, more robust capacitors for industrial HVAC systems. Geographic market variations also play a role, as demand can differ significantly between regions based on climate, economic conditions, and regulatory environments.

IV. Pricing Policies

A. Cost Structure of Air Conditioning Capacitors

The pricing of air conditioning capacitors is influenced by several factors, including raw material costs and manufacturing expenses.

1. **Raw Material Costs**: The cost of materials used in capacitor production, such as aluminum and plastic, can fluctuate based on market conditions. These fluctuations can directly impact the final price of capacitors.

2. **Manufacturing and Labor Costs**: Labor costs, energy prices, and manufacturing efficiency also play a significant role in determining the overall cost structure of capacitors.

B. Pricing Strategies

Manufacturers employ various pricing strategies to remain competitive in the market.

1. **Competitive Pricing**: Many manufacturers adopt competitive pricing strategies to attract customers, especially in a market with numerous players.

2. **Value-Based Pricing**: Some companies may choose to implement value-based pricing, where the price is set based on the perceived value of the product to the customer rather than solely on production costs.

C. Impact of Tariffs and Trade Policies

Tariffs and trade policies can significantly affect the pricing of air conditioning capacitors. For instance, tariffs on imported materials or components can increase production costs, which may be passed on to consumers. Additionally, trade policies can influence the availability of certain materials, further impacting pricing strategies.

V. Innovation and Technology

A. Advances in Capacitor Technology

The air conditioning capacitor market is witnessing rapid technological advancements.

1. **Improved Efficiency and Longevity**: New materials and manufacturing techniques are leading to capacitors that are more efficient and have longer lifespans. This not only benefits manufacturers but also provides consumers with more reliable products.

2. **Smart Capacitors and IoT Integration**: The integration of smart technology into capacitors is becoming increasingly common. Smart capacitors can communicate with HVAC systems to optimize performance and energy usage, aligning with the growing trend of IoT (Internet of Things) in home and commercial automation.

B. Research and Development Policies

Government incentives for research and development (R&D) can stimulate innovation in the capacitor market. Collaboration between industry and academia can lead to breakthroughs in capacitor technology, enhancing efficiency and sustainability.

VI. Environmental and Sustainability Policies

A. Eco-Friendly Capacitor Materials

As environmental concerns grow, manufacturers are increasingly focusing on eco-friendly materials for capacitor production. This shift not only helps meet regulatory requirements but also appeals to environmentally conscious consumers.

B. Recycling and Disposal Regulations

Proper recycling and disposal of capacitors are critical to minimizing environmental impact. Regulations governing the disposal of electronic waste are becoming more stringent, prompting manufacturers to develop recycling programs and sustainable disposal methods.

C. Corporate Social Responsibility Initiatives

Many companies are adopting corporate social responsibility (CSR) initiatives that focus on sustainability and environmental stewardship. These initiatives can enhance a company's reputation and appeal to consumers who prioritize eco-friendly practices.

VII. Challenges and Opportunities

A. Challenges Facing the Air Conditioning Capacitor Market

The air conditioning capacitor market faces several challenges, including:

1. **Supply Chain Disruptions**: Global supply chain disruptions, exacerbated by events such as the COVID-19 pandemic, can impact the availability of raw materials and components, leading to production delays.

2. **Regulatory Compliance Costs**: The costs associated with meeting regulatory requirements can be significant, particularly for smaller manufacturers who may lack the resources to navigate complex compliance landscapes.

B. Opportunities for Growth

Despite these challenges, there are numerous opportunities for growth in the air conditioning capacitor market:

1. **Emerging Markets**: As developing countries continue to urbanize and experience rising temperatures, the demand for air conditioning systems—and, by extension, capacitors—is expected to grow.

2. **Increasing Demand for Energy-Efficient Solutions**: The global push for energy efficiency presents a significant opportunity for manufacturers to innovate and develop capacitors that meet the needs of energy-conscious consumers.

VIII. Conclusion

In summary, the market policies governing air conditioning capacitors are shaped by a complex interplay of regulatory frameworks, market dynamics, pricing strategies, technological advancements, and environmental considerations. As the demand for air conditioning systems continues to rise, manufacturers must adapt to changing policies and market conditions to remain competitive. The future outlook for the air conditioning capacitor market is promising, with opportunities for growth driven by innovation, sustainability, and the increasing need for energy-efficient solutions.

IX. References

- Academic journals on HVAC technology and environmental regulations.

- Industry reports from market research firms analyzing trends in the air conditioning capacitor market.

- Government publications outlining energy efficiency standards and environmental regulations.

This comprehensive overview of market policies for air conditioning capacitors highlights the importance of understanding the regulatory landscape, market dynamics, and technological advancements that shape this critical industry. As the world continues to grapple with climate change and energy efficiency, the role of capacitors in HVAC systems will only become more significant.