Development Trends in the Capacitor Factory Industry

I. Introduction

Capacitors are essential components in electronic devices, serving as energy storage units that help regulate voltage and power flow. They play a critical role in various applications, from consumer electronics to automotive systems and renewable energy solutions. The capacitor factory industry, which focuses on the manufacturing of these vital components, has seen significant evolution over the years. This article aims to explore the current development trends in the capacitor factory industry, highlighting technological advancements, market dynamics, sustainability efforts, and future outlooks.

II. Historical Context

The history of capacitor technology dates back to the 18th century with the invention of the Leyden jar, one of the first capacitors. Over the years, capacitor technology has evolved significantly, leading to the development of various types of capacitors, including ceramic, electrolytic, film, and tantalum capacitors. The manufacturing processes have also advanced, transitioning from manual assembly to automated production lines. Key milestones in the capacitor factory industry include the introduction of new materials, such as tantalum and polymers, which have enhanced performance and reliability.

III. Current Market Landscape

A. Overview of the Global Capacitor Market

The global capacitor market has experienced substantial growth, driven by the increasing demand for electronic devices and the expansion of various industries. According to recent market research, the capacitor market is projected to reach USD 30 billion by 2025, growing at a CAGR of 5.5%. Key players in the industry include companies like Murata Manufacturing, Vishay Intertechnology, and KEMET Corporation, which dominate the market with their innovative products and extensive distribution networks.

B. Types of Capacitors Produced

Capacitors come in various types, each suited for specific applications:

1. **Ceramic Capacitors**: Widely used in consumer electronics due to their small size and reliability.

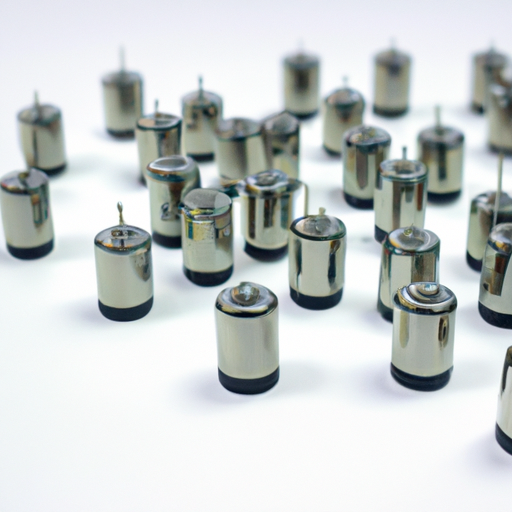

2. **Electrolytic Capacitors**: Commonly found in power supply circuits, known for their high capacitance values.

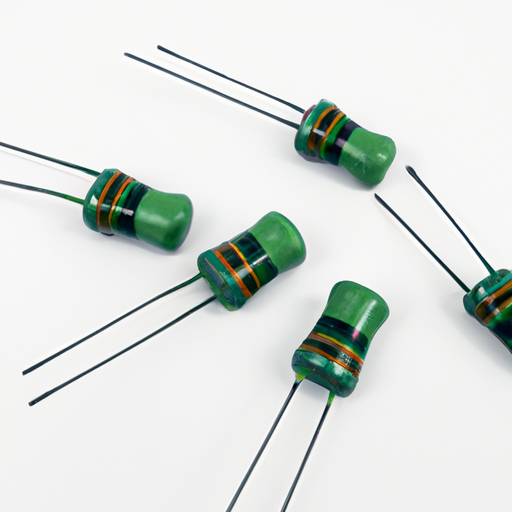

3. **Film Capacitors**: Preferred for applications requiring stability and low losses, such as audio equipment.

4. **Tantalum Capacitors**: Valued for their compact size and high capacitance, often used in military and aerospace applications.

C. Applications of Capacitors in Various Sectors

Capacitors are integral to numerous sectors:

1. **Consumer Electronics**: Used in smartphones, tablets, and laptops to manage power and improve performance.

2. **Automotive**: Essential for electric vehicles (EVs) and advanced driver-assistance systems (ADAS).

3. **Industrial**: Employed in machinery and automation systems to ensure smooth operation.

4. **Renewable Energy**: Critical for energy storage solutions and power management in solar and wind energy systems.

IV. Technological Advancements

A. Innovations in Capacitor Materials

Recent advancements in capacitor materials have led to the development of high-capacitance materials that enhance performance. The use of nanotechnology in capacitors has also gained traction, allowing for the creation of smaller, more efficient components that can store more energy in a compact form.

B. Manufacturing Process Improvements

The manufacturing processes in the capacitor industry have seen significant improvements, particularly with the integration of automation and robotics. Automated production lines increase efficiency and reduce human error, while lean manufacturing principles help minimize waste and optimize resource use.

C. Advances in Testing and Quality Control

Quality control is paramount in capacitor manufacturing. Enhanced testing methodologies, including real-time monitoring systems, ensure that capacitors meet stringent performance standards. These advancements help manufacturers identify defects early in the production process, reducing costs and improving product reliability.

V. Sustainability and Environmental Considerations

A. Shift Towards Eco-Friendly Materials

As environmental concerns grow, the capacitor industry is shifting towards eco-friendly materials. Manufacturers are exploring alternatives to traditional materials that may have harmful environmental impacts, focusing on sustainable sourcing and production methods.

B. Energy-Efficient Manufacturing Processes

Energy efficiency in manufacturing processes is becoming a priority. Companies are investing in technologies that reduce energy consumption during production, contributing to lower carbon footprints and operational costs.

C. Recycling and End-of-Life Management of Capacitors

The recycling of capacitors is gaining attention as part of a broader effort to promote circular economy practices. Manufacturers are developing programs to manage the end-of-life of capacitors, ensuring that materials are reused and waste is minimized.

VI. Market Demand and Consumer Trends

A. Increasing Demand for Miniaturization in Electronics

The trend towards miniaturization in electronics is driving demand for smaller, more efficient capacitors. As devices become more compact, manufacturers are challenged to produce capacitors that meet these size constraints without compromising performance.

B. Growth of Electric Vehicles and Their Impact on Capacitor Demand

The rise of electric vehicles is significantly impacting capacitor demand. Capacitors are crucial for energy storage and management in EVs, leading to increased investment in capacitor technology to support this growing market.

C. Rise of Renewable Energy Sources and Energy Storage Solutions

The shift towards renewable energy sources is creating new opportunities for the capacitor industry. Capacitors play a vital role in energy storage solutions, helping to stabilize power supply and improve the efficiency of renewable energy systems.

VII. Challenges Facing the Industry

A. Supply Chain Disruptions

The capacitor industry faces challenges related to supply chain disruptions, exacerbated by global events such as the COVID-19 pandemic. Manufacturers must navigate shortages of raw materials and components, impacting production timelines and costs.

B. Competition from Alternative Technologies

Competition from alternative technologies, such as supercapacitors and batteries, poses a challenge for traditional capacitor manufacturers. To remain competitive, companies must innovate and differentiate their products.

C. Regulatory Challenges and Compliance

Regulatory challenges and compliance with environmental standards are increasingly important in the capacitor industry. Manufacturers must stay informed about changing regulations and ensure that their products meet safety and environmental requirements.

VIII. Future Outlook

A. Predictions for the Capacitor Factory Industry

The future of the capacitor factory industry looks promising, with continued growth expected as demand for electronic devices, electric vehicles, and renewable energy solutions rises. Innovations in materials and manufacturing processes will drive advancements in capacitor technology.

B. Emerging Markets and Opportunities

Emerging markets, particularly in Asia and Africa, present significant opportunities for capacitor manufacturers. As these regions experience economic growth and increased investment in technology, the demand for capacitors is likely to rise.

C. Potential for Collaboration and Partnerships in Research and Development

Collaboration and partnerships in research and development will be crucial for driving innovation in the capacitor industry. By working together, manufacturers, research institutions, and technology companies can develop new materials and technologies that enhance capacitor performance and sustainability.

IX. Conclusion

In summary, the capacitor factory industry is undergoing significant transformation, driven by technological advancements, market demand, and sustainability efforts. The importance of innovation and eco-friendly practices cannot be overstated, as they will shape the future of capacitors in technology. As the industry continues to evolve, manufacturers must remain agile and responsive to changing market dynamics to thrive in this competitive landscape.

X. References

A comprehensive list of academic papers, industry reports, and articles used for research will be provided to support the insights and data presented in this article.

---

This blog post provides a detailed exploration of the development trends in the capacitor factory industry, covering historical context, current market dynamics, technological advancements, sustainability efforts, and future outlooks. Each section is designed to inform readers about the complexities and opportunities within this vital industry.