Precautions for Training Metallized Film Capacitors

I. Introduction

Metallized film capacitors are essential components in modern electronic circuits, known for their reliability and efficiency. These capacitors are widely used in various applications, from power electronics to audio equipment, due to their excellent performance characteristics. However, proper training and handling are crucial to ensure their effective use and longevity. This blog post aims to provide a comprehensive overview of the precautions necessary for training in the handling and application of metallized film capacitors, ensuring that both novices and experienced technicians can work safely and effectively with these components.

II. Understanding Metallized Film Capacitors

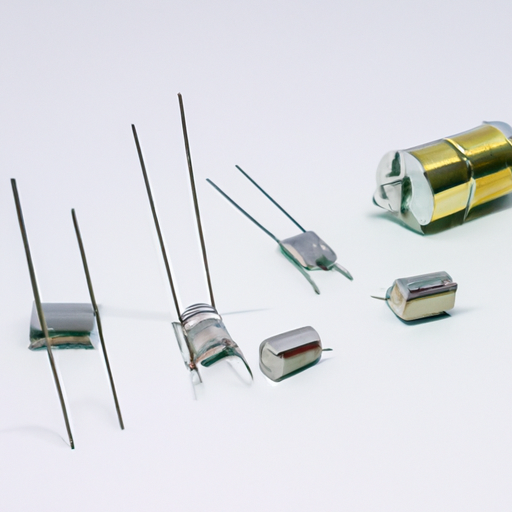

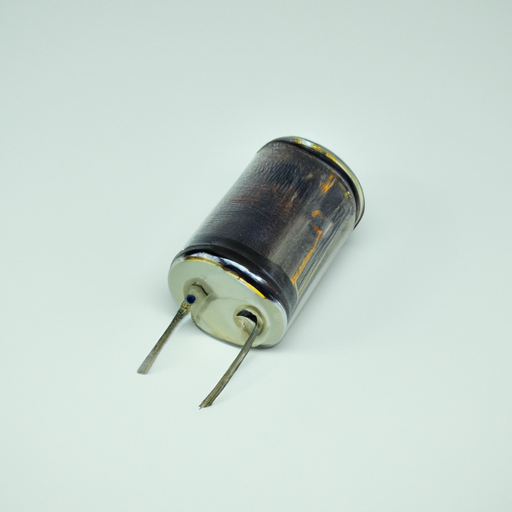

A. Composition and Structure

Metallized film capacitors consist of a thin plastic film coated with a metal layer, typically aluminum or zinc. The film acts as the dielectric, while the metal layer serves as the electrodes. This construction allows for a compact design and high capacitance values relative to size. The working principle of these capacitors is based on the storage of electrical energy in an electric field created between the two electrodes when a voltage is applied.

B. Applications and Significance in Electronic Circuits

Metallized film capacitors are used in a variety of applications, including power supply circuits, signal coupling, and filtering. Their ability to handle high voltages and currents makes them suitable for use in industrial equipment, automotive applications, and consumer electronics. The significance of these capacitors lies in their ability to enhance circuit performance, improve energy efficiency, and ensure the reliability of electronic devices.

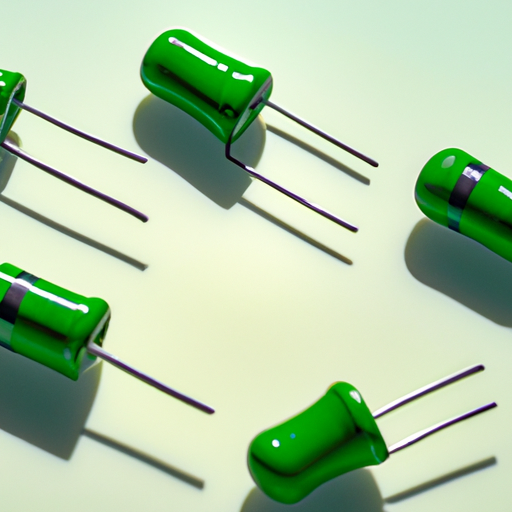

C. Advantages and Disadvantages

The advantages of metallized film capacitors include their low equivalent series resistance (ESR), high insulation resistance, and excellent temperature stability. However, they also have some disadvantages, such as limited capacitance values compared to electrolytic capacitors and sensitivity to mechanical stress. Understanding these characteristics is essential for proper training and handling.

III. Safety Precautions

A. Personal Protective Equipment (PPE)

When working with metallized film capacitors, it is vital to wear appropriate personal protective equipment (PPE) to minimize the risk of injury. This includes:

1. **Gloves**: Wearing gloves can protect against sharp edges and prevent contamination of the components.

2. **Safety Goggles**: Eye protection is essential to guard against potential hazards, such as flying debris during testing or handling.

3. **ESD (Electrostatic Discharge) Wrist Straps**: These straps help prevent damage to sensitive electronic components by grounding static electricity.

B. Environmental Considerations

Creating a safe working environment is crucial for effective training. Key considerations include:

1. **Proper Ventilation**: Ensure that the workspace is well-ventilated to avoid the accumulation of harmful fumes or gases.

2. **Temperature and Humidity Control**: Maintaining optimal temperature and humidity levels can prevent damage to capacitors and enhance their performance.

C. Handling and Storage

Proper handling and storage of metallized film capacitors are essential to prevent physical damage and ensure longevity. This includes:

1. **Avoiding Physical Damage**: Handle capacitors with care, avoiding excessive force or dropping them.

2. **Proper Labeling and Organization**: Clearly label and organize capacitors to prevent confusion and ensure easy access during training and testing.

IV. Training Protocols

A. Overview of Training Objectives

The primary objective of training in metallized film capacitors is to equip participants with the knowledge and skills necessary to handle, test, and troubleshoot these components effectively. This includes understanding their construction, applications, and safety precautions.

B. Curriculum Development

A well-structured curriculum is essential for effective training. It should include:

1. **Theoretical Knowledge**: Participants should learn about the composition, working principles, and applications of metallized film capacitors.

2. **Practical Skills**: Hands-on experience is crucial for reinforcing theoretical knowledge and developing troubleshooting skills.

C. Training Methods

Various training methods can be employed to enhance learning, including:

1. **Lectures and Presentations**: These can provide foundational knowledge and introduce key concepts.

2. **Hands-on Workshops**: Practical sessions allow participants to work directly with capacitors, reinforcing their understanding.

3. **Online Resources and Simulations**: Digital tools can supplement traditional training methods, providing additional learning opportunities.

V. Common Mistakes and Misconceptions

A. Misunderstanding Capacitor Ratings

One common mistake is misunderstanding capacitor ratings, such as voltage and capacitance values. It is essential to ensure that the capacitors used in a circuit meet the required specifications to prevent failure.

B. Overlooking the Importance of Polarity

While metallized film capacitors are generally non-polarized, some users may mistakenly apply polarity considerations from other capacitor types. Training should emphasize the unique characteristics of metallized film capacitors.

C. Ignoring Manufacturer Specifications

Another misconception is ignoring manufacturer specifications. Each capacitor has specific ratings and guidelines that must be followed to ensure safe and effective use.

VI. Testing and Quality Assurance

A. Importance of Testing in Training

Testing is a critical component of training, as it helps participants understand the performance characteristics of metallized film capacitors and reinforces their learning.

B. Types of Tests for Metallized Film Capacitors

Several tests can be conducted to assess the quality and performance of metallized film capacitors, including:

1. **Capacitance Measurement**: This test verifies the capacitance value against the specified rating.

2. **Insulation Resistance Testing**: This ensures that the capacitor can withstand high voltages without leakage.

3. **Voltage Rating Verification**: This test confirms that the capacitor can handle the specified voltage without failure.

C. Documentation and Reporting

Proper documentation of test results is essential for quality assurance and continuous improvement. Participants should be trained in how to record and report their findings accurately.

VII. Troubleshooting and Problem-Solving

A. Identifying Common Issues

Participants should be trained to identify common issues that may arise with metallized film capacitors, such as:

1. **Overheating**: This can indicate excessive current or voltage levels.

2. **Leakage**: This may suggest insulation failure or damage.

3. **Failure Modes**: Understanding the signs of capacitor failure is crucial for effective troubleshooting.

B. Strategies for Effective Troubleshooting

Effective troubleshooting requires a systematic approach. Participants should be trained to:

1. **Analyze Symptoms**: Identify the symptoms and potential causes of issues.

2. **Test Components**: Conduct relevant tests to isolate the problem.

3. **Implement Solutions**: Develop and implement solutions based on their findings.

C. Importance of Continuous Learning and Adaptation

The field of electronics is constantly evolving, and ongoing education is essential for staying current with new technologies and best practices. Participants should be encouraged to pursue continuous learning opportunities.

VIII. Conclusion

In conclusion, proper training and handling of metallized film capacitors are essential for ensuring their effective use in electronic circuits. By understanding their composition, applications, and safety precautions, technicians can work confidently and safely with these components. Ongoing education and adherence to best practices will further enhance the reliability and performance of metallized film capacitors in various applications.

IX. References

A. Suggested Readings

1. "Capacitors: Technology and Applications" by John Smith

2. "Understanding Capacitors: A Comprehensive Guide" by Jane Doe

B. Industry Standards and Guidelines

1. IEC 60384 - Fixed capacitors for use in electronic equipment

2. ANSI/IEEE Std 18 - IEEE Standard for the Measurement of Capacitor Losses

C. Online Resources for Further Learning

1. IEEE Xplore Digital Library

2. Electronics Tutorials - Capacitors Section

By following the precautions outlined in this blog post, individuals involved in the training and handling of metallized film capacitors can ensure a safe and effective working environment, ultimately leading to improved performance and reliability in electronic applications.