What are the Manufacturing Processes for the Latest Capacitors?

I. Introduction

Capacitors are fundamental components in modern electronics, serving as energy storage devices that can release energy quickly when needed. They play a crucial role in various applications, from power supply circuits to signal processing in communication devices. As technology advances, so does the need for more efficient, reliable, and compact capacitors. This blog post will explore the latest manufacturing processes for capacitors, highlighting the innovations and challenges faced by manufacturers in this ever-evolving field.

II. Types of Capacitors

Capacitors come in various types, each with unique characteristics and applications:

A. Ceramic Capacitors

Ceramic capacitors are widely used due to their small size, high reliability, and low cost. They are commonly found in applications such as decoupling and filtering in electronic circuits.

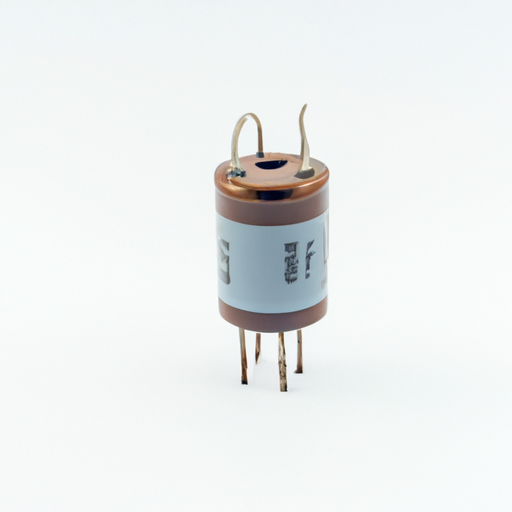

B. Electrolytic Capacitors

Electrolytic capacitors are known for their high capacitance values and are often used in power supply circuits. They are polarized, meaning they have a positive and negative terminal, which limits their application in AC circuits.

C. Film Capacitors

Film capacitors are made from thin plastic films and are known for their stability and low loss. They are often used in audio applications and power electronics.

D. Tantalum Capacitors

Tantalum capacitors offer high capacitance in a small package and are used in applications requiring high reliability, such as military and aerospace electronics.

E. Supercapacitors

Supercapacitors, or ultracapacitors, provide high energy density and rapid charge/discharge capabilities. They are increasingly used in renewable energy systems and electric vehicles.

III. Overview of Manufacturing Processes

The manufacturing of capacitors involves several general steps:

A. General Steps in Capacitor Manufacturing

1. **Material Selection**: Choosing the right materials is crucial for the performance and reliability of capacitors.

2. **Component Fabrication**: This involves creating the individual components of the capacitor, such as electrodes and dielectrics.

3. **Assembly**: The components are assembled into a complete capacitor.

4. **Testing and Quality Control**: Rigorous testing ensures that the capacitors meet industry standards and specifications.

IV. Detailed Manufacturing Processes

A. Ceramic Capacitors

1. **Material Preparation**: The process begins with the preparation of ceramic powders, which are mixed with additives to achieve desired properties.

2. **Die Pressing and Sintering**: The mixed powders are pressed into shapes and then sintered at high temperatures to form a solid ceramic body.

3. **Electrode Application**: Electrodes are applied to the ceramic body, typically using a screen printing process.

4. **Final Assembly and Testing**: The capacitors are assembled, and final testing is conducted to ensure they meet specifications.

B. Electrolytic Capacitors

1. **Anode Foil Preparation**: The anode foil is prepared by etching aluminum or tantalum to increase surface area.

2. **Oxide Layer Formation**: An oxide layer is formed on the anode foil through an electrochemical process, which acts as the dielectric.

3. **Electrolyte Filling**: The capacitor is filled with an electrolyte, which is essential for its operation.

4. **Sealing and Testing**: The capacitor is sealed to prevent leakage, followed by rigorous testing for quality assurance.

C. Film Capacitors

1. **Film Production**: Thin polymer films are produced, which serve as the dielectric material.

2. **Metallization Process**: A metal layer is applied to the film, creating the electrodes.

3. **Winding and Cutting**: The metallized film is wound into a cylindrical shape and cut to the desired size.

4. **Encapsulation and Testing**: The capacitors are encapsulated to protect them from environmental factors, followed by testing.

D. Tantalum Capacitors

1. **Tantalum Powder Preparation**: Tantalum powder is prepared and compacted to form the anode.

2. **Anode Formation**: The anode is formed through a sintering process.

3. **Dielectric Layer Formation**: An oxide layer is formed on the tantalum anode, which serves as the dielectric.

4. **Assembly and Testing**: The capacitor is assembled and tested for performance and reliability.

E. Supercapacitors

1. **Electrode Material Preparation**: Carbon-based materials are prepared for the electrodes, which provide high surface area.

2. **Electrolyte Selection**: The choice of electrolyte is critical for the performance of supercapacitors.

3. **Cell Assembly**: The electrodes and electrolyte are assembled into cells.

4. **Testing and Quality Assurance**: Each cell undergoes testing to ensure it meets performance standards.

V. Innovations in Capacitor Manufacturing

The capacitor manufacturing industry is witnessing several innovations:

A. Advances in Materials Science

New materials are being developed to enhance the performance of capacitors, such as high-k dielectrics that allow for smaller and more efficient designs.

B. Automation and Industry 4.0

Manufacturers are increasingly adopting automation and smart manufacturing techniques to improve efficiency and reduce costs.

C. Environmental Considerations and Sustainability

There is a growing emphasis on sustainable manufacturing practices, including the use of eco-friendly materials and processes.

D. Miniaturization and High-Capacity Designs

As electronic devices become smaller, the demand for miniaturized capacitors with high capacitance values is increasing, driving innovation in design and manufacturing.

VI. Challenges in Capacitor Manufacturing

Despite advancements, the capacitor manufacturing industry faces several challenges:

A. Material Sourcing and Cost

The sourcing of high-quality materials can be challenging and costly, impacting overall production costs.

B. Quality Control and Reliability

Ensuring consistent quality and reliability in capacitor production is critical, especially for applications in safety-critical systems.

C. Meeting Industry Standards and Regulations

Manufacturers must navigate complex industry standards and regulations, which can vary by region and application.

VII. Future Trends in Capacitor Manufacturing

The future of capacitor manufacturing is likely to be shaped by several trends:

A. Emerging Technologies

Technologies such as nanotechnology are expected to play a significant role in developing new capacitor designs with enhanced performance.

B. Potential Applications in Renewable Energy and Electric Vehicles

As the demand for renewable energy solutions and electric vehicles grows, capacitors will play a crucial role in energy storage and management.

C. The Role of Capacitors in the Internet of Things (IoT)

With the proliferation of IoT devices, the need for compact, efficient capacitors will continue to rise, driving innovation in the industry.

VIII. Conclusion

In summary, capacitors are essential components in modern electronics, and their manufacturing processes are continually evolving. From ceramic to supercapacitors, each type has its unique manufacturing challenges and innovations. As the industry faces challenges related to material sourcing, quality control, and regulatory compliance, ongoing research and development will be crucial for future advancements. The future of capacitor manufacturing looks promising, with emerging technologies and applications poised to drive growth and innovation in this vital sector.

IX. References

1. Academic journals on capacitor technology and manufacturing processes.

2. Industry reports detailing trends and innovations in capacitor manufacturing.

3. Manufacturer specifications and guidelines for various types of capacitors.

This comprehensive overview of capacitor manufacturing processes highlights the importance of these components in modern electronics and the ongoing advancements that will shape their future.