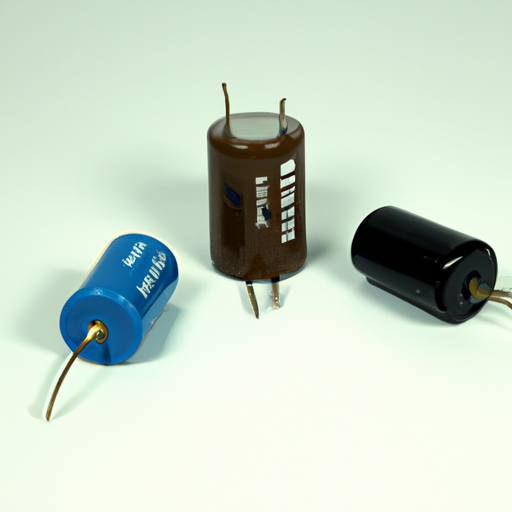

The Latest Electrolytic Capacitor Specifications

I. Introduction

Electrolytic capacitors are essential components in modern electronic circuits, playing a crucial role in energy storage, filtering, and signal coupling. These capacitors are characterized by their ability to store a large amount of electrical energy in a relatively small volume, making them indispensable in various applications, from consumer electronics to industrial machinery. This article aims to provide an overview of the latest specifications and advancements in electrolytic capacitors, highlighting their importance in the ever-evolving landscape of electronics.

II. Overview of Electrolytic Capacitors

A. Basic Structure and Working Principle

Electrolytic capacitors consist of two conductive plates, known as the anode and cathode, separated by an electrolyte. The anode is typically made of aluminum or tantalum, while the cathode is often a conductive liquid or solid. The electrolyte serves as a medium that allows ions to move between the plates, enabling the capacitor to store electrical energy. When a voltage is applied, an oxide layer forms on the anode, which acts as a dielectric, allowing the capacitor to hold a charge.

B. Types of Electrolytic Capacitors

1. **Aluminum Electrolytic Capacitors**: These are the most common type, known for their high capacitance values and relatively low cost. They are widely used in power supply circuits and audio applications.

2. **Tantalum Electrolytic Capacitors**: Tantalum capacitors offer higher capacitance in a smaller package compared to aluminum capacitors. They are known for their stability and reliability, making them suitable for critical applications in aerospace and medical devices.

3. **Other Variations**: Conductive polymer capacitors are a newer type that combines the benefits of electrolytic capacitors with lower equivalent series resistance (ESR) and improved performance at high frequencies.

III. Key Specifications of Electrolytic Capacitors

A. Capacitance Values

Electrolytic capacitors are available in a wide range of capacitance values, typically from a few microfarads (µF) to several thousand microfarads. The choice of capacitance is crucial in circuit design, as it directly affects the capacitor's ability to store energy and filter signals. Recent advancements have led to the development of high-capacitance capacitors that can meet the demands of modern electronics, such as power supply decoupling and energy storage in renewable energy systems.

B. Voltage Ratings

Voltage ratings indicate the maximum voltage a capacitor can handle without breaking down. Understanding these ratings is essential for ensuring the reliability and safety of electronic circuits. Recent trends show an increase in voltage ratings, with manufacturers producing capacitors that can withstand higher voltages, catering to the needs of high-power applications and electric vehicles.

C. Temperature Ratings

Electrolytic capacitors are rated for specific operating temperature ranges, typically from -40°C to +105°C. The performance and lifespan of these capacitors can be significantly affected by temperature. Innovations in materials and design have led to capacitors that can operate effectively at higher temperatures, enhancing their reliability in demanding environments.

D. Ripple Current Ratings

Ripple current refers to the AC component of the current flowing through a capacitor, which can cause heating and affect performance. Understanding ripple current ratings is vital for applications where capacitors are subjected to fluctuating currents, such as in power supplies. Recent advancements have improved the ability of electrolytic capacitors to handle higher ripple currents, making them more suitable for high-performance applications.

IV. Performance Characteristics

A. Equivalent Series Resistance (ESR)

Equivalent Series Resistance (ESR) is a critical parameter that affects the efficiency and performance of electrolytic capacitors. It represents the resistive losses within the capacitor and can lead to heat generation during operation. Recent developments have focused on producing low ESR capacitors, which enhance efficiency and reduce power loss, particularly in high-frequency applications.

B. Lifetime and Reliability

The lifespan of electrolytic capacitors is influenced by various factors, including temperature, voltage, and ripple current. Manufacturers are continually innovating to enhance the reliability of these components, employing advanced materials and manufacturing techniques to improve performance and extend lifespan. Capacitors with longer lifetimes are particularly important in applications where maintenance is challenging, such as in automotive and aerospace systems.

C. Leakage Current

Leakage current is the small amount of current that flows through a capacitor even when it is not in use. High leakage current can lead to energy loss and affect the performance of electronic circuits. Recent trends in capacitor design have focused on reducing leakage current, resulting in more efficient and reliable components.

V. Applications of Electrolytic Capacitors

Electrolytic capacitors find applications across a wide range of industries:

A. Consumer Electronics

In consumer electronics, electrolytic capacitors are commonly used in power supplies, audio equipment, and signal processing circuits. Their ability to store large amounts of energy makes them ideal for applications requiring smooth power delivery.

B. Industrial Applications

In industrial settings, electrolytic capacitors are used in motor drives, power conditioning, and energy storage systems. Their reliability and performance under varying conditions make them suitable for demanding applications.

C. Automotive Electronics

The automotive industry relies heavily on electrolytic capacitors for various functions, including power management, infotainment systems, and safety features. With the rise of electric vehicles, the demand for high-performance capacitors has increased significantly.

D. Renewable Energy Systems

Electrolytic capacitors play a vital role in renewable energy systems, such as solar inverters and wind turbines. They help manage energy storage and ensure stable power delivery, contributing to the efficiency of these systems.

VI. Recent Innovations and Trends

A. Advancements in Materials and Manufacturing Processes

Recent innovations in materials, such as the use of conductive polymers and advanced electrolytes, have led to the development of capacitors with improved performance characteristics. Additionally, advancements in manufacturing processes have enabled the production of capacitors with tighter tolerances and higher reliability.

B. Miniaturization and High-Density Capacitors

As electronic devices become smaller and more compact, the demand for miniaturized and high-density capacitors has increased. Manufacturers are responding by developing capacitors that offer higher capacitance values in smaller packages, allowing for more efficient use of space in electronic designs.

C. Environmental Considerations and RoHS Compliance

With growing environmental concerns, manufacturers are increasingly focusing on producing capacitors that comply with RoHS (Restriction of Hazardous Substances) regulations. This shift towards environmentally friendly materials and processes is essential for sustainable electronics manufacturing.

D. Smart Capacitors and Integration with IoT

The rise of the Internet of Things (IoT) has led to the development of smart capacitors that can communicate with other devices and systems. These capacitors can monitor their performance and provide real-time data, enhancing the efficiency and reliability of electronic systems.

VII. Conclusion

In summary, electrolytic capacitors are vital components in modern electronics, with specifications that continue to evolve to meet the demands of various applications. From advancements in capacitance and voltage ratings to innovations in materials and manufacturing processes, the landscape of electrolytic capacitors is dynamic and ever-changing. For design engineers and manufacturers, staying updated with the latest specifications is crucial for ensuring the reliability and performance of electronic systems. As technology continues to advance, the future of electrolytic capacitors looks promising, with ongoing innovations that will further enhance their capabilities and applications.

VIII. References

1. "Electrolytic Capacitors: A Comprehensive Guide," Journal of Electronic Components, 2023.

2. "Advancements in Capacitor Technology," IEEE Transactions on Industrial Electronics, 2023.

3. Manufacturer specifications from leading capacitor manufacturers.

4. "The Role of Capacitors in Renewable Energy Systems," Renewable Energy Journal, 2023.

This blog post provides a detailed overview of the latest specifications and advancements in electrolytic capacitors, highlighting their importance in various applications and the ongoing innovations that shape their future.