What are the Product Standards for Thick Film Resistors?

I. Introduction

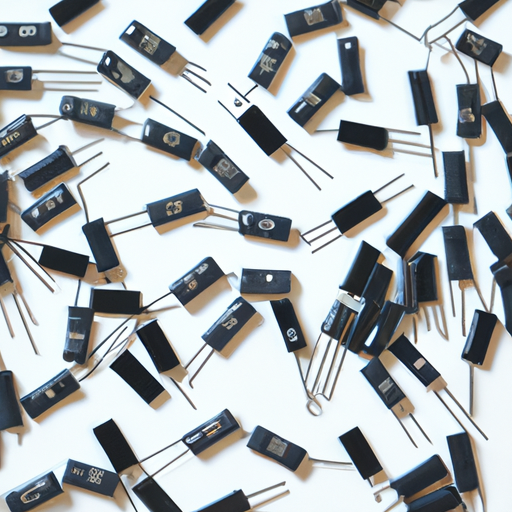

Thick film resistors are essential components in modern electronic devices, playing a critical role in controlling current and voltage levels. These resistors are characterized by their unique manufacturing process, which involves applying a thick layer of resistive material onto a substrate. As the demand for reliable and high-performance electronic components continues to grow, the importance of product standards for thick film resistors cannot be overstated. This blog post aims to explore the various product standards that govern thick film resistors, their significance, and the challenges faced in meeting these standards.

II. Understanding Thick Film Resistors

A. Composition and Manufacturing Process

Thick film resistors are typically made from a combination of materials, including ceramic substrates and conductive pastes. The manufacturing process begins with the preparation of a ceramic substrate, which provides the necessary mechanical support and thermal stability. A resistive paste, composed of metal oxides and glass frit, is then screen-printed onto the substrate. This layer is subsequently fired at high temperatures, allowing the materials to bond and form a stable resistive layer.

B. Characteristics and Applications

Thick film resistors exhibit a range of electrical properties, including resistance values, tolerance, and temperature coefficients. They are available in various resistance values, typically ranging from a few ohms to several megaohms, with tolerances that can be as low as 1%. These resistors are widely used in various applications, including automotive electronics, telecommunications, consumer electronics, and industrial equipment, due to their reliability and performance.

III. Importance of Product Standards

Product standards play a crucial role in ensuring the reliability and performance of thick film resistors. They provide a framework for manufacturers to follow, ensuring that their products meet specific quality and safety requirements. Additionally, adherence to product standards facilitates compatibility and interchangeability among components, which is essential for manufacturers and designers. Furthermore, compliance with regulatory standards is vital for ensuring safety and environmental protection, particularly in industries such as automotive and aerospace.

IV. Key Product Standards for Thick Film Resistors

A. International Standards

1. IEC Standards

The International Electrotechnical Commission (IEC) has established several standards relevant to thick film resistors. The IEC 60115 series outlines the general specifications for fixed resistors, including thick film types. This series covers various aspects, such as electrical performance, environmental conditions, and testing methods. The IEC 61000 series addresses electromagnetic compatibility (EMC), ensuring that electronic components, including resistors, do not interfere with each other.

2. ISO Standards

The International Organization for Standardization (ISO) has developed standards that are crucial for quality management and environmental practices. ISO 9001 focuses on quality management systems, ensuring that manufacturers implement processes that consistently meet customer and regulatory requirements. ISO 14001 addresses environmental management systems, promoting sustainable practices in manufacturing.

B. National Standards

In addition to international standards, various national standards govern thick film resistors. The American National Standards Institute (ANSI) provides guidelines for electrical components in the United States. The Japanese Industrial Standards (JIS) set forth specifications for electronic components in Japan. In Europe, the EN standards provide a framework for ensuring product safety and performance.

C. Industry-Specific Standards

Certain industries have established specific standards for thick film resistors. For example, the Automotive Electronics Council (AEC) has developed AEC-Q200, which outlines reliability requirements for passive components used in automotive applications. Similarly, military standards, such as MIL-PRF-55342, specify performance and reliability criteria for resistors used in military and aerospace applications.

V. Testing and Quality Assurance

A. Types of Tests for Thick Film Resistors

To ensure compliance with product standards, thick film resistors undergo various testing procedures. Electrical testing involves measuring resistance values and voltage ratings to verify performance. Environmental testing assesses the resistor's ability to withstand temperature cycling, humidity, and other environmental factors. Mechanical testing evaluates the resistor's durability under conditions such as vibration and shock.

B. Certification Processes

Certification processes are essential for ensuring that thick film resistors meet established standards. Third-party testing laboratories play a crucial role in this process, conducting independent evaluations of resistor performance. Additionally, traceability and documentation are vital for maintaining quality assurance, allowing manufacturers to track the production and testing of their components.

VI. Challenges in Meeting Product Standards

Despite the importance of product standards, manufacturers face several challenges in meeting these requirements. Variability in manufacturing processes can lead to inconsistencies in product quality, making it difficult to achieve compliance. Furthermore, the rapid evolution of technology and standards necessitates continuous adaptation by manufacturers. Global supply chain considerations also pose challenges, as components sourced from different regions may be subject to varying standards and regulations.

VII. Future Trends in Thick Film Resistor Standards

As technology advances, the standards governing thick film resistors are also evolving. One significant trend is the development of new materials and manufacturing techniques that enhance performance and reliability. Additionally, the increasing demand for miniaturization and integration in electronic devices is driving the need for smaller and more efficient resistors. Sustainability and environmental considerations are also becoming more prominent, with manufacturers seeking to reduce their environmental impact through eco-friendly practices and materials.

VIII. Conclusion

In conclusion, product standards for thick film resistors are essential for ensuring the quality, reliability, and safety of these critical electronic components. By adhering to established standards, manufacturers can enhance their products' performance and facilitate compatibility across various applications. As technology continues to evolve, it is crucial for manufacturers and designers to prioritize compliance with these standards to meet the growing demands of the electronics industry. By doing so, they can contribute to the development of high-quality, reliable electronic components that meet the needs of consumers and industries alike.

IX. References

1. IEC 60115 Series - Fixed Resistors for Use in Electronic Equipment.

2. IEC 61000 Series - Electromagnetic Compatibility (EMC).

3. ISO 9001 - Quality Management Systems.

4. ISO 14001 - Environmental Management Systems.

5. AEC-Q200 - Reliability Standards for Passive Components in Automotive Applications.

6. MIL-PRF-55342 - Military Specification for Thick Film Resistors.

7. ANSI Standards - American National Standards Institute.

8. JIS Standards - Japanese Industrial Standards.

This blog post provides a comprehensive overview of the product standards for thick film resistors, highlighting their significance in the electronics industry and the challenges faced by manufacturers in meeting these standards.